We are committed to the quality of our articles. It is also just as important to us that our piping, cords, braids, galloons, edgings and all other products are produced under fair and ethically sound working conditions. Thanks to our production site in North-Rhine Westphalia’s Wuppertal, we are well positioned in this respect. For instance, in addition to pay based on collective bargaining, we also ensure that the working environment is safe and poses no risk to health.

Fair fashion – fair working conditions

For this reason, FRIEBA has committed to the Code of Conduct (CoC), which was created by the Gesamtverband der deutschen Textil- und Modeindustrie and its member associations. This code of conduct is considered a guideline for socially responsible business practices and provides a framework for orientation, which companies can align their individual corporate policy with. The CoC is oriented towards international standards and legal requirements. It contains fundamental rules based on practice, which serve to support the implementation of human rights, occupational, social and ecological standards in all areas of business. They include, among other things, fair business practices such as an employee-oriented HR policy, protection of the climate and the environment as well as the responsible use of natural resources. Inhumane practices such as child labour and forced labour are expressly prohibited.

Social responsibility for our employees

Without the people who use their skills and energy to create our products, we wouldn’t be the company we are today. Everyone is part of the whole and instrumental for the resulting quality and success. That’s why, for us, paying equitable wages and guaranteeing good working conditions is a matter of course. All employees at FRIEBA are employed in salaried positions. We offer a safe and clean working environment and have taken all the due precautions for people and the environment, wages based on collective bargaining, continued payment of wages in the event of illness, holiday pay and annual bonus payments.

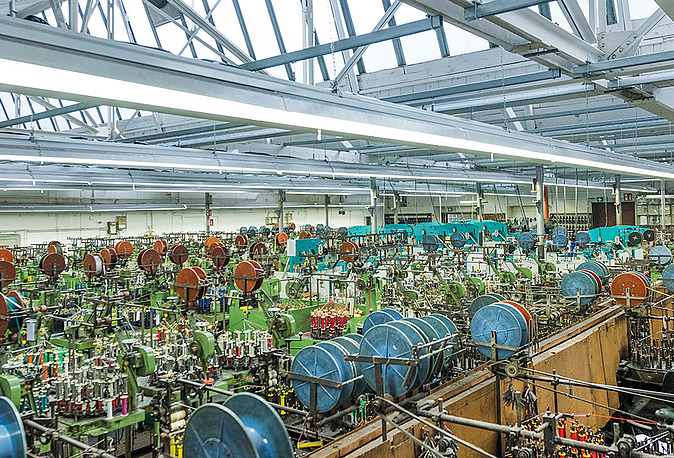

For example, a major issue in our production is the high noise level in the weaving workshop where at times 200 braiding machines operate simultaneously. In order to protect the hearing of the people who work there as best possible, we manufacture individual ear protection for every employee and perform medical exams on a regular basis.

As a family-owned and operated company with a long tradition in the textile industry located in the Bergisches Land region, we are also very committed to treating our employees with respect and like family. That’s why many of them stay with our establishment their entire working life. We hold regular events to celebrate the work anniversaries of employees, who have worked for FRIEBA for 25 years or farewell parties for employees who are retiring. This also includes our collective meal at the end of the year or the obligatory extra half-day of vacation for all children’s birthdays.

Textile craft – made in Germany

Our braiding and crocheting machines are not computers operated with the click of a mouse. Some of our braiding machines have been used for nearly 100 years and themselves require plenty of care in the form of maintenance. All machines are set up by hand, modified and readjusted every time the article is changed.

This requires a great deal of skill, technical expertise and good instincts when it comes to sensitive material. Then there’s the fact that the threads are subjected to considerable tensile forces during processing. If the machines are not operated correctly during the manufacturing or setup process, the thread can tear or the article will not have the desired appearance and is therefore defective. In many cases, mere nuances in connection with the configuration of the machine are what determine how the article will look. Extensive experience and technical finesse are needed in this area.

As a result, our teams in the braiding and weaving shop are only made up of highly specialised experts, who have either learned their craft at our establishment or whom we have trained further. Our plant leader is also the examiner at the chamber of industry and commerce, but also an instructor at the training centre. On one hand, we train employees ourselves because specialists who have completed relevant training in our area are virtually non-existent on the free job market. This means that there are fewer and fewer manufacturing textile operations in Germany and, as a result, fewer properly trained specialists. On the other hand, we have high standards when it comes to employee expertise.

Handling the braiding and crochet galloon machines is based to a large extent on long-term experience and expertise. The three-year training required to become a manufacturer of decorative textiles (textile production mechanic) is only able to convey the basics. More independent knowledge can only be acquired through daily work (set-up, care, knowledge of materials, etc.) and regular continuing and further education.

Fashion and more

No doubt about it, not just expertise is decisive when it comes to manufacturing our textile products. Even when it comes to selecting raw materials, we have high quality standards. For instance, at our company, we only process ultra high-quality threads made of natural and synthetic fibres such as Egyptian cotton, GOTS-certified cotton, Enka® viscose, polyester Diolen®, Lurex®, etc. All materials purchased comply with the STANDARD 100 by OEKO-TEX®.

As a manufacturer of textile accessories, we not only carry great responsibility towards our employees, customers and suppliers, but also towards the environment. We are expressly against the painful practice of “mulesing” in sheep farming and only use “non-mulesed” merino wool to manufacture our articles.

Of course, these standards in terms of materials, but also fair, socially-responsible working conditions and high ecological standards have their price. This is one of the reasons why most of our braiding, crocheting and woven articles are valued by customers from the middle to upper price segments. Apart from fashion labels, they also include stage designers, theatres, hotels, museums or furniture manufacturers from around Europe. In most cases, manufacturers of so-called fast-fashion articles rely on the Asian market.

Colour charts and pattern cards with original articles

As our collection consists of several thousand different articles, it is essential that customers know exactly what kind of quality, feel and colour they will be getting before they make their decision to buy. That’s why we use originals of our articles on pattern cards. We have these exceedingly elaborate pattern cards and colour charts made by a local master bookbinder.

By the way, all of our pattern cards are now also available for download digitally as high-resolution PDFs to give our customers a first impression of our articles. The digital collection not only facilitates communication between ourselves and our customers, but also our customers’ communication at meetings or with their production sites. This avoids sending out pattern cards unnecessarily, which in turn benefits the climate and the environment.